As a trusted horizontal CNC machine manufacturer, we offer machines with a Box-in-Box structure designed for enhanced performance and precision. Our horizontal CNC machines are built with reinforced body structures that deliver exceptional rigidity, supporting high-speed cutting and optimal accuracy. The Box-in-Box structure is specifically engineered to suppress vibration, extend tool life, and enhance workpiece quality during horizontal CNC machining. Key machine features include effective vibration suppression, which ensures smoother operations, while improved tool longevity reduces overall maintenance costs. With reduced processing time and increased accuracy in contour machining, our CNC horizontal machining centers also deliver superior surface finishing for even the most complex projects. Please don't hesitate to contact us.

As a leading manufacturer of advanced CNC machinery, we proudly offer the CNC Horizontal Machining Center with a Box-in-Box structure, a revolutionary design that sets new standards in precision and performance. Our commitment to excellence is evident in the innovative features of this machining center, which is engineered to deliver unparalleled accuracy, reliability, and efficiency in a variety of industrial applications.

VHL1200ATC (VHL1600ATC; VHL2000ATC)

Spindle

Table Diameter (mm): Ø 1250 (1600; 2000)

Maximum Rotating Diameter (mm): Ø 1600 (2000; 2500)

Maximum Cutting Diameter (mm): Ø 1350 (1800; 2300)

Maximum Cutting Height (mm): 1200 (1200;1600)

X1-Axis Travel (mm): -600, +875 (-600, +1500; -600, +1350)

Z1-Axis Travel (mm):

900 (900; 950)

Crossbeam Vertical Travel (mm): 800 (800; 1150)

Spindle Motor (kW):

37/45 (37/45; 60/75)

Side Axis

X2-Axis Travel (mm):

1720 (1720; 1720)

Z2-Axis Travel (mm):

800 (800; 950)

Second Spindle Motor (kW): 7.5/11 (7.5/11; 11/15)

Covered area (mm): 10500x6000 (12500x6200; 14500x6500)

Machine Height (mm): 5500 (5500; 6500);

Covered area (mm): 4000x4800 (4600x5200; 5300x5500)

Machine Height (mm): 4950 (5400; 5300)

Features

The Box-in-Box body structure enhances rigidity and pairs with high-speed cutting capabilities to ensure high-quality processing performance. This design effectively controls tool vibration, extends tool life, and improves workpiece processing accuracy.

Machine Features:

Effective vibration suppression

Extended tool life

Improved processing accuracy

Reduced processing time

Enhanced surface finishing accuracy

Increased contour machining accuracy

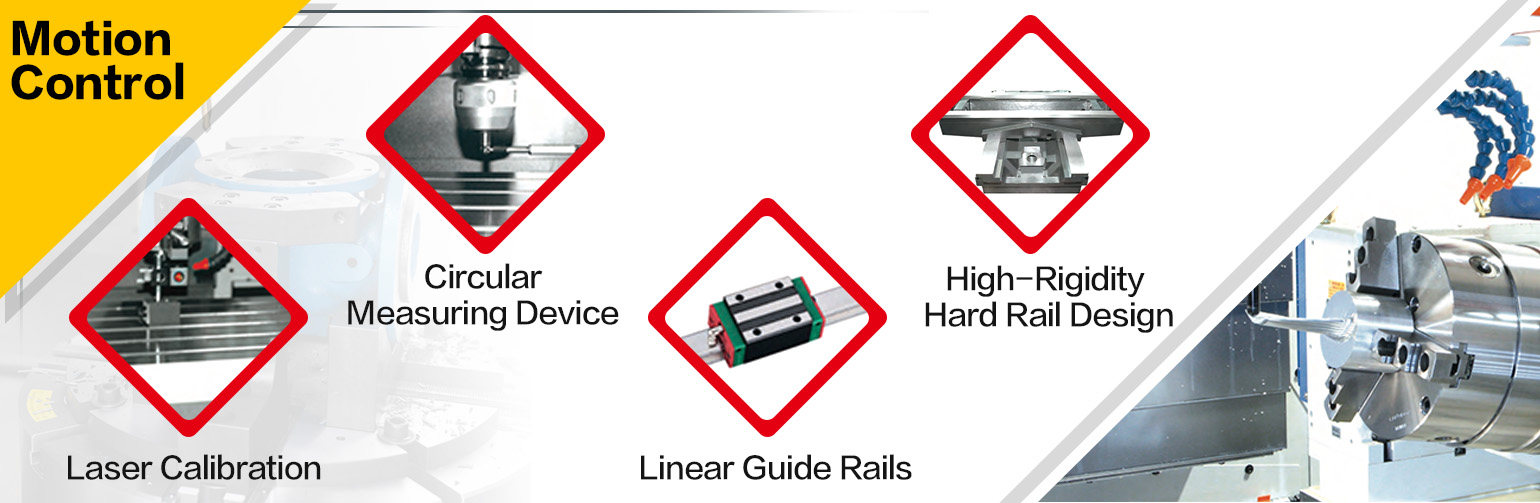

X-Axis Dual Servo Motor Synchronous Drive:

The servo synchronization offers stable and rapid feed characteristics, avoiding the inertial sway issues that occur with single servo motor drives. It provides higher cutting force and minimizes the vibration generated by the tool tip during Y-axis movement, extending tool life and improving processing accuracy.

X-Axis Sliding Table:

The X-axis sliding table features a large span design with high-performance rolling linear guides, dual ball screws, and dual servo motors, ensuring fast displacement, high precision, and excellent dynamic stability.

Z-Axis Sliding Table:

The Z-axis sliding table employs linear rolling guide design, providing superior high-speed cutting capabilities and high load characteristics during heavy-duty cutting.

The CNC Horizontal Machining Center boasts a robust Box-in-Box structure, a hallmark of its design that enhances rigidity and stability. This advanced structural reinforcement effectively minimizes tool vibration, which is critical for extending tool life and ensuring high-quality processing performance. By controlling vibrations and improving workpiece accuracy, this design significantly reduces processing time and enhances surface finishing, making it ideal for high-precision tasks.

One of the standout features of our machining center is the X-Axis dual servo motor synchronous drive. This system provides stable and rapid feed characteristics, eliminating the inertial sway typically associated with single servo motor drives. The result is a higher cutting force with minimized vibration, further extending tool life and improving overall processing accuracy.

The X-Axis sliding table is designed with high-performance rolling linear guides and dual ball screws, ensuring fast displacement and exceptional dynamic stability. Its large span design enhances precision and speed, while the Y-Axis sliding table, made from high-grade cast iron, offers excellent shock absorption and high-speed displacement capabilities. This dual sliding table design supports heavy-duty cutting performance, overcoming resonance issues and ensuring consistent high-speed operations.

For the Z-Axis, we utilize a linear rolling guide design, providing superior cutting capabilities and load-bearing characteristics during heavy-duty tasks. This setup ensures reliable performance even under challenging conditions.

Our CNC Horizontal Machining Center is available in a range of models and specifications to meet diverse industrial needs. From the HMC500 to the HMC2000, each model is designed to offer precise X, Y, and Z-axis travels, high spindle speeds, and robust spindle motor power. The machine's worktable area and covered dimensions are optimized to accommodate various workpieces, ensuring versatility and efficiency in production environments.

In summary, our CNC Horizontal Machining Center with a Box-in-Box structure represents the pinnacle of modern machining technology. It combines advanced design with superior performance, making it an indispensable tool for achieving high precision and productivity in any machining operation.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.